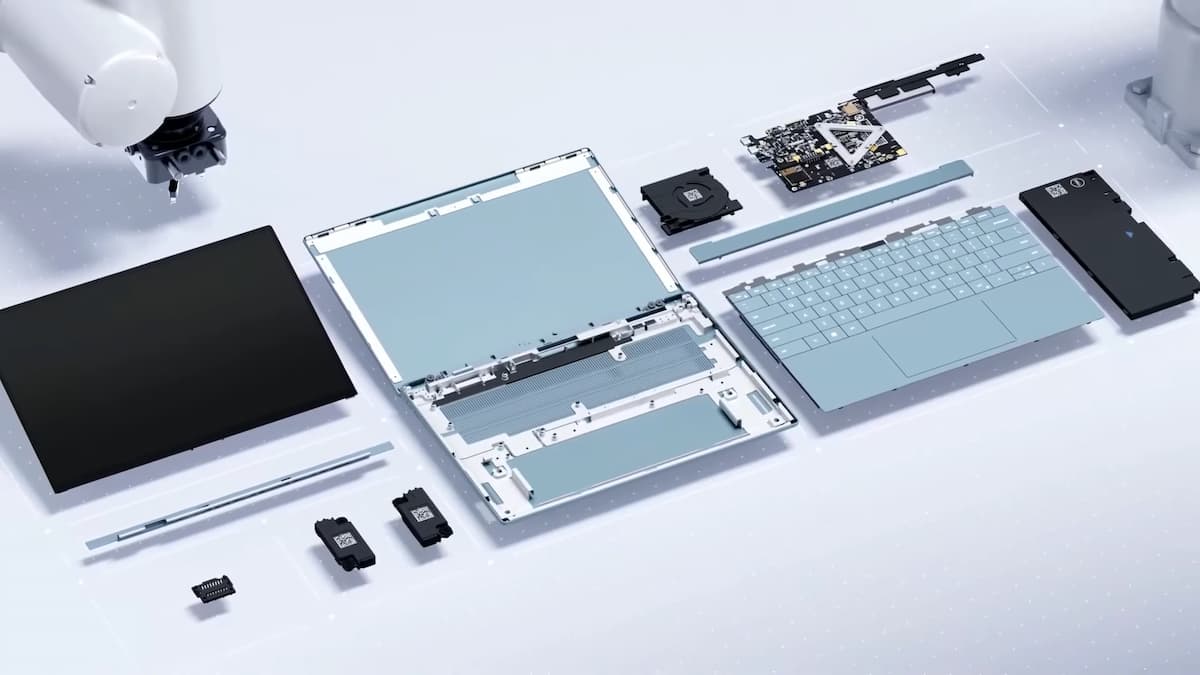

Dell has developed a new type of laptop that can be disassembled into individual blocks or modules, allowing users to upgrade or repair specific components faster and more easily.

A modular design, in addition to allowing its users to exchange old or defective parts on their own, instead of simply replacing the entire device, also creates the conditions for the equipment to be more sustainable and profitable in the long term.

Dell presented new details about its modular computer

The modular design follows a similar logic to Lego pieces. In the case of a computer, if it is designed under this modality, its components can be updated or repaired by its own users, instead of sending the complete equipment for repair or replacing it with a new one.

In the long term, the adoption of this design modality brings implications at the level of profitability, due to the extension of its useful life and, therefore, the reduction of expenses associated with the complete replacement of equipment. Similarly, at the sustainability level, this design could lead to a reduction in electronic waste, one of the great environmental problems of our times, since users can individually repair or replace some components, instead of getting rid of them. the entire device, as is often the case today.

The projection of a longer useful life for a modular computer lies not only in the possibilities of repair, but also in its possibilities of improvement, since the replaceable modules corresponding to critical components of the equipment, such as processors, graphics cards and storage units , can be renewed by others of greater capacity or power.

The conceptual design of this prototype, called Luna, it was presented in December of last year. Now, a year later, Dell unveiled new advances achieved with this project, including a video testimonial.

While only a screwdriver is needed to open the chassis, the rest of the modules can be removed without special tools. Components like the keyboard, monitor, fans, battery, motherboard, and speakers could be replaced by any average user, or a robot could do the same job. This last possibility is already being explored by Dell, who already have in mind the creation of a two-armed industrial disassembly robot, designed to extract and sort computer parts.

Another objective pursued by this project is the creation of a system that solves the problem of computer maintenance in a fully automated way. The aforementioned disassembling robot is only one part of this equation, which, in Dell’s shared vision, could be complemented with a system capable of adequately detecting the wear of individual modules or hardware components at different stages of their useful life.

As it is still a prototype from a research project, there are still no estimated dates for its commercial launch or an estimated price.

While more and more industries focus on sustainability as the way to project themselves into the future, in the case of computers —and consumer electronics in general— modular design seems to be one of the most interesting ways to address this issue. sight.