The highly integrated semiconductor industry is overwhelmingly dominated by just three companies: TSMC, Intel and Samsung. The first of them leads this market with a share of 54%, while Samsung follows at some distance with 17%, and Intel is on the heels of the latter with a slightly lower share than that of this South Korean company. All the others are kept far away from these three.

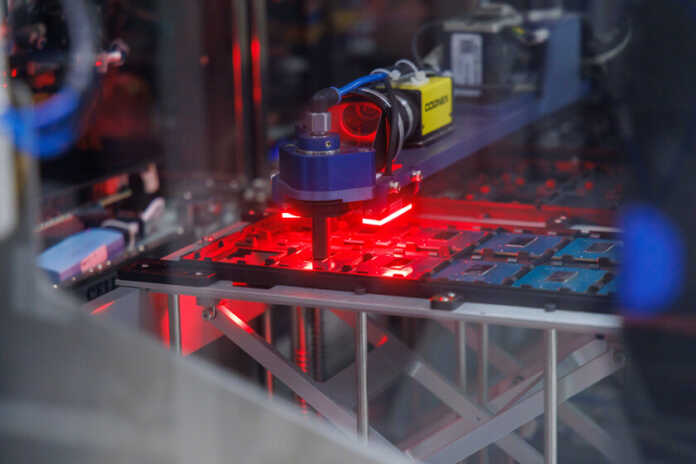

These numbers reflect an unappealable reality: TSMC occupies an indisputable leadership position, but it would be a mistake to underestimate a company with the resources that Intel has for many lurches it has taken in recent years. In fact, we recently had the opportunity to visit its R&D facilities in Haifa (Israel), and the itinerary handled by its engineers is clearly increase competitiveness of the photolithographic processes you are about to use.

Intel 4 photolithography is here, and 18 angstroms will arrive in 2025

During our visit to the most important facilities that Intel has in Israel, we participated in a technical session in which Shlomit Weiss, who is the head of the company’s design and engineering division, confirmed that are meeting deadlines that they have set their sights on when it comes to the development of their semiconductor manufacturing technologies. In fact, it is likely that they will even advance some of the milestones that had been set.

Chip production on the large-scale Intel 4 node was initially going to start in 2023, but Weiss confirmed during his conference that they are ready to go. during the last quarter of 2022so the arrival of the first chips employing this integration technology is literally just around the corner.

The Raptor Lake microprocessors, which will be the next chips of the Intel Core family that will reach our computers, will be produced with Intel 7 photolithography, so, in theory, the chips manufactured in the Intel 4 node will be 21.5% more powerful without its consumption being affected. Or they will give us a similar power, but consuming 40% less. Doesn’t sound bad, and of course we’ll check it out when the time comes and we get a chance to test them thoroughly.

The next step it will take is to adopt Intel node 3, which will be relatively painless to roll out because, on paper, it will make it easier for microprocessor designers to move their designs from Intel node 4. And not much beyond that. , in 2025, Intel plans to have its photolithography of 18 angstroms (10 angstroms equals 1nm), although it seems unlikely that in just three years it will be ready to start large-scale chip production using this integration technology.

The slide that we publish below these lines contains two notes that are worth not overlooking. The first of them reflects the importance of artificial intelligence not only as a fundamental part of the software that supervises in real time the processing of each thread of execution (thread); also insinuates the role that this discipline has in the process of CPU microarchitecture design from Intel. We will talk about this strategy in much more depth in an article that we are preparing and that we will publish at the end of this month.

The other note worth noting suggests the effort that Intel is making to improve the quality of your processes semiconductor manufacturing. The performance of a production node is conditioned by an infinite number of factors, and all chip manufacturers without exception seek to minimize the number of integrated circuits per silicon wafer that have been damaged during the transfer of the geometric pattern contained in the mask to the wafer and its subsequent handling.

This improvement in the quality of the processes involved in manufacturing is crucial to enable large-scale production of chips using new photolithography. Of one thing we can be sure: during the next few years the competition from a technological point of view between the main semiconductor manufacturers will reach an unprecedented intensity. And we will be here to tell you about it in detail.