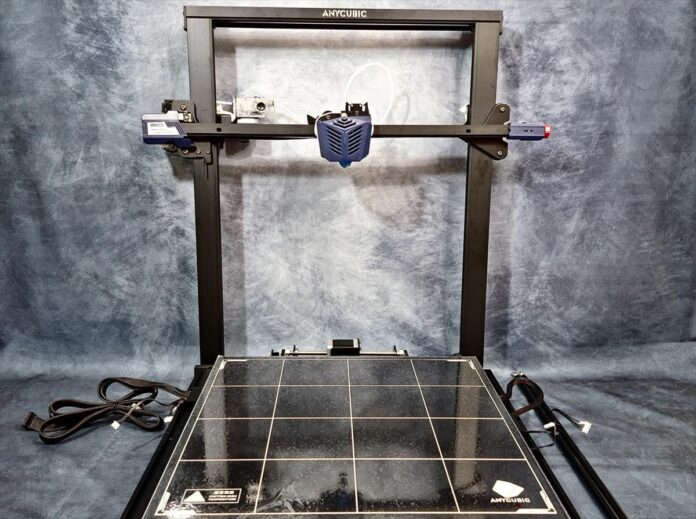

Anycubic has presented a new filament 3D printer, the Kobra Max, to print large volumes, easy to use and running in less than 45 minutes.

We are talking about a printer with leviQ 25 point auto-leveling system, 32-bit motherboard, 402 x 402 x 452 mm build volume, layer height: 0.1 mm to 0.3 mm (nozzle 0, 4mm), recommended print speed of 70-90mm/s and capable of printing on various materials, such as PLA, TPU, ABS, PETG and others.

With a carborundum glass bed and a 4.3” color touch screen based interface, it is ideal for beginners and advanced users alike.

Inside the box we have power cord, filament holder, sample filament, spatula tool, viewing screen, extra nozzle, vertical stabilizers, pre-assembled printer frame, pre-assembled base with electronics and bed, SD card and USB reader, side cutters, wrenches and Allen keys, USB cable to connect the printer to the PC and user manual.

It all takes about 30 minutes to assemble, as the Kobra Max base can be built with just eleven screws: four for the frame and three for the LCD screen. The LCD screen is attached with two screws. After that, there are four screws for the vertical support rods. The ribbon cable plug needs to be inserted into the printhead assembly after we have finished assembling the printer.

In this video you have the initial configuration

We go to the leveling, and for this we click on ‘Auto-leveling’ in the menu. Use 25 different points on the printer bed as a starting point. After that, you will return to the level up menu. Depending on the number of prints, it’s important to level it at least once a week to be safe.

The bed itself is huge, with a roughened surface effective at retaining prints until ready. High-quality printing is made possible by Kobra’s HC32F460 CPU and 32-bit motherboard, though the printer is fairly quiet. Printer noise is mainly generated by the 4010 fan and the motherboard fan. At full speed, the fans produce a noise level of 54 to 56 decibels, but can be made quieter by reducing their speed.

The printer can print large amounts of material at a faster rate as it grabs and transports the filament very efficiently. Retraction requires some fine tuning to prevent string movement, which is noticeable on larger diameter collets such as 0.8mm.

You can print with various materials. in tests with PETG filament it printed at 230°C on the hotend and 80°C on the bed without any problem. You will also need to print at a slower speed while using PETG (in this case at 45mm and the fan speed is set to 40%). PETG will have a lower shrink distance so I chose a 3mm to 5mm shrink distance for my PETG.

Advantages of Anycubic Kobra Max

– Easy to set up and use for beginners

– Build quality and print quality.

– Automatic bed leveling out of the box

– 2209 controllers in SPI/UART mode

– silent stepper motors

– Tension adjuster on the X and Y axes

– Carborundum glass bed

– Massive build volume 402x402x452mm

Disadvantages of Anycubic Kobra Max

– Need more options on screen for calibration

The Anycubic Kobra max is a good investment, available for 570 euros on its official website or 599 euros on amazon.